- 07272-228575

- info@bakulcasting.com

BAKUL FIBER Stainless Steel Fibers substantially improve refractories durability performance in petrochemical, metals, chemical general industrial applications

Bakul shot has longer life than other peening media, The information supplied by an accurate life test & the Casts associated with shot changes such as machine down time, labour involved in Cleaning out the machine & shot reclamation may also be reduced by using Bakul shot.

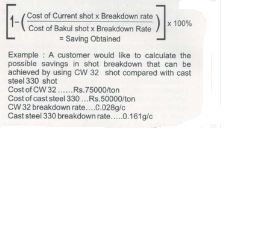

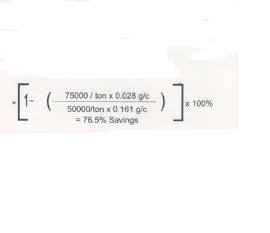

Example: A customer would like to calculate the possible savings in shot breakdown that can be achieved by using CW 32 shot compared with cast steel 330 shot Cost of CW 32…… Rs.75000/ton Cost of cast steel 330…Rs.50000/ton CW 32 breakdown rate….C.028g/c Cast steel 330 breakdown rate…..0.161g/c

Casts associated with shot changes such as machine down time, labour involved in Cleaning out the machine & shot reclamation may also be reduced by using Bakul shot.

Example: A customer would like to calculate the possible savings in shot breakdown that can be achieved by using CW 32 shot compared with cast steel 330 shot Cost of CW 32…… Rs.75000/ton Cost of cast steel 330…Rs.50000/ton CW 32 breakdown rate….C.028g/c Cast steel 330 breakdown rate…..0.161g/c

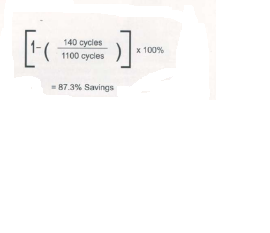

Cast Steel 330 for 20% Breakdown ……….. 140 cycles CW32 for 20% Breakdowm …………….. 1100 cycles

we are the only ISO certified manufacturer of CUT WIRE shot peening shot to SAEJ 441

specification. Hard shot give Almen specs and are ECONOMICAL, due to longer wear life. Shot peening if done with cast shot defeat the purpose of shot peening as cast shot break and broken sharp edges of shot produce nicks which can be starting point of crack. Correctly rounded cut wire SHOT WITH CORRECT hardness